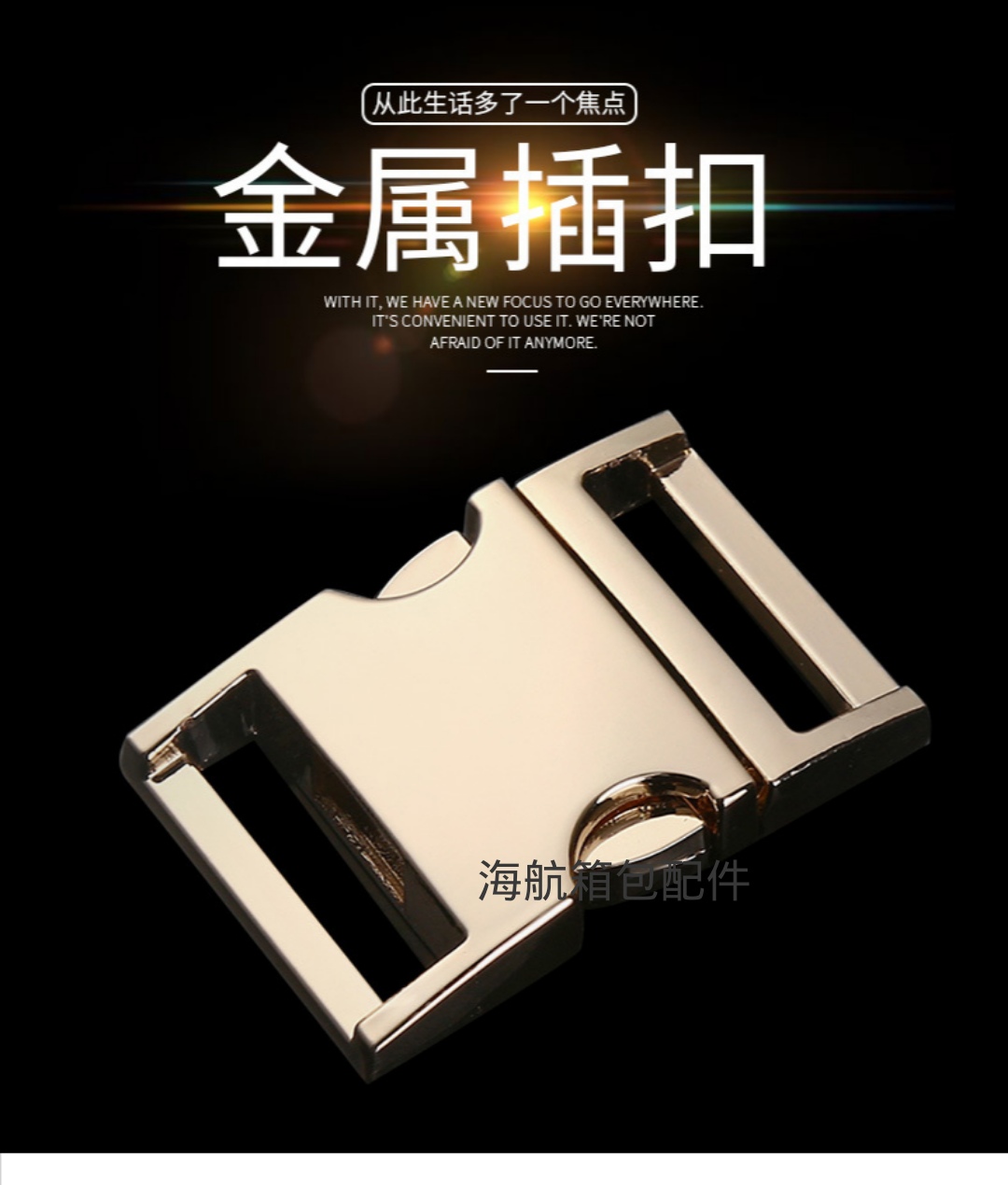

Details determine success or failure: a little knowledge of metal fasteners

In our daily life, there are countless seemingly insignificant but play a key role in small objects, metal fasteners is one of them. As a common connection tool, metal fasteners are widely used in clothing, hardware accessories and even home decoration and other fields. They can not only ensure the safety of fixed items, but also often become designers to express creativity, add aesthetic elements. For example, in high-end clothing, a delicate metal fastener can greatly enhance the texture of the whole piece of clothing; in hardware products, it is the basic component to ensure structural stability and safety.

From Raw Material to Finished Product: The Secret of Manufacturing Process

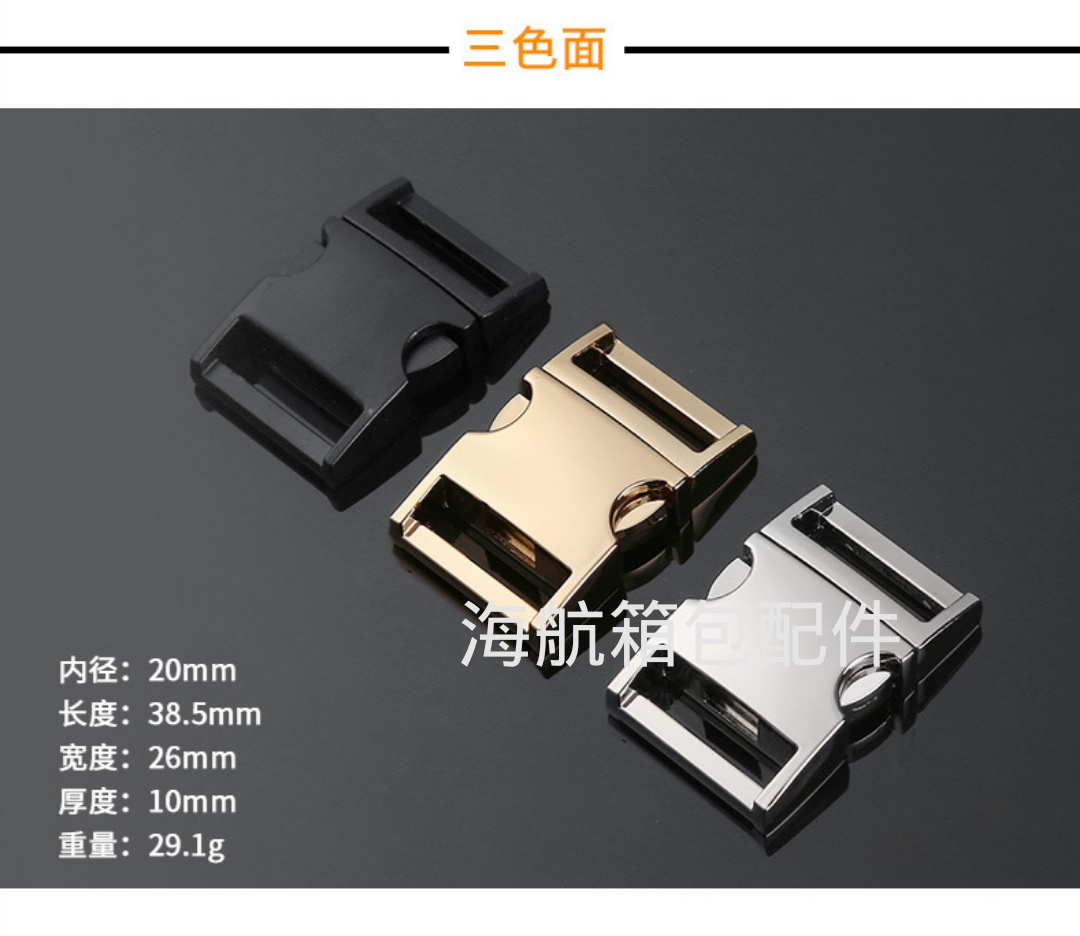

Behind the high-quality metal fasteners is a series of sophisticated production processes. First of all, it is very important to choose the right raw materials. Usually, stainless steel, copper alloy and other metal materials with strong corrosion resistance and easy processing are selected. Next, after cutting, stamping, grinding and a series of processes, forming a preliminary shape. Finally, through electroplating or other surface treatment technology, give the fastener beautiful color and stronger anti-wear performance. Every step requires strict quality control to ensure that the final product meets high standards.

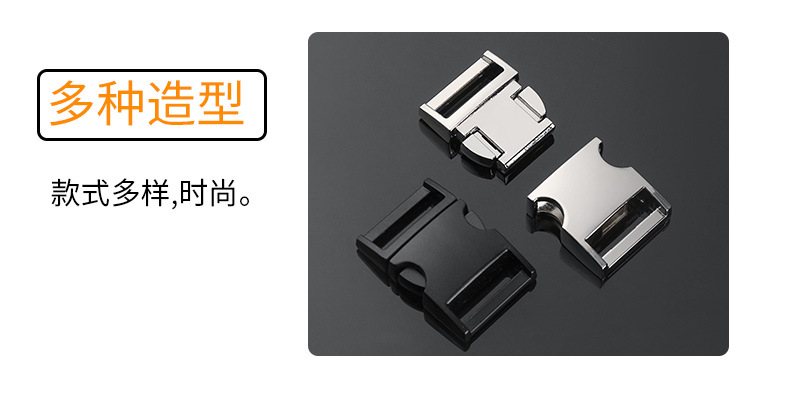

The Power of Design: Innovation Leads the Future

Design is not only the beautification of appearance, but also the perfect combination of function and aesthetics. There are many distinctive metal fastener designs on the market, such as bionic designs that imitate natural biological forms and traditional patterns that integrate ethnic customs. These unique designs not only enhance the added value of products, but also promote the innovation and development of related industries. For example, the retro-style belt buckle launched by a well-known brand has won the favor of consumers with its fine hand-carved and classic design.

Quality First: Inspection and Certification System

In order to protect the rights and interests of consumers, major manufacturers will strictly implement a complete quality management system. From the incoming inspection of raw materials to the factory test of finished products, every link has strict control. At the same time, samples will be regularly sent to third-party authorities for professional evaluation, and international certification certificates such as ISO9001 and CE will be obtained to prove the safety and reliability of the products. Only after layers of screening products, in order to eventually go to the market, to serve the vast number of consumers.

Application scenarios: from clothing to furniture

The application range of metal fasteners is extremely wide. In the field of clothing, it is an important accessory for fixing the skirt and decorating the neckline; in the manufacture of bags, it plays the role of convenient switch, firm and durable; and in furniture assembly, it is an ideal choice for rapid installation and size adjustment. Not only that, with the advancement of science and technology, metal fasteners have also begun to enter smart wearable devices, automotive interiors and other industries, showing unlimited development potential.

Maintenance Guide: Let Beauty Continue

Although metal fasteners have strong weather resistance and anti-aging ability, they still need proper maintenance to extend their service life. It is recommended to avoid using hard brushes or cleaners containing abrasive ingredients when cleaning to prevent scratching the surface. If it is not used for a long time, it is best to store it in a dry and ventilated place to prevent corrosion. In addition, for those easy to loose parts, regular inspection and timely fastening is also very necessary.

Customer Witness: Real Evaluation and Feedback

"As a fashion designer, I often use various types of metal fasteners. The texture of this product is very good, strong and beautiful, which completely exceeds my expectations." -- Miss Zhang (fashion designer)

"I recently bought this set of furniture to decorate my new house and found that all the drawers are fixed with such metal fasteners. The opening and closing are smooth and silent, and it looks very upscale, so it's really worth the money!" -Mr. Lee (Housewife)

Environmental protection concept: the responsibility of green manufacturing

As society pays more and more attention to environmental protection issues, more and more companies begin to pay attention to environmental friendliness in the production process. In this regard, excellent metal fastener manufacturers have achieved the goal of zero discharge of production wastewater and emission of exhaust gas by adopting advanced production equipment and technology. In addition, it also actively promotes the circular economy model, encourages the recycling of scrap metals, and makes due contributions to the construction of a harmonious ecology.

purchasing skills: insight into gold

in the face of a dazzling array of metal fasteners market, how to pick out the most suitable for their own that one? the following are a few tips:

-clear purpose: first of all, to clear the purpose of purchase, is for home or commercial, or the needs of special scenarios.

-Focus on material: High-quality metal fasteners are generally made of stainless steel, zinc alloy and other materials, which have good corrosion resistance and strength.

-Consider design: Good design can not only increase the practicality of the product, but also bring visual enjoyment.

-View Certification: Formal Brand