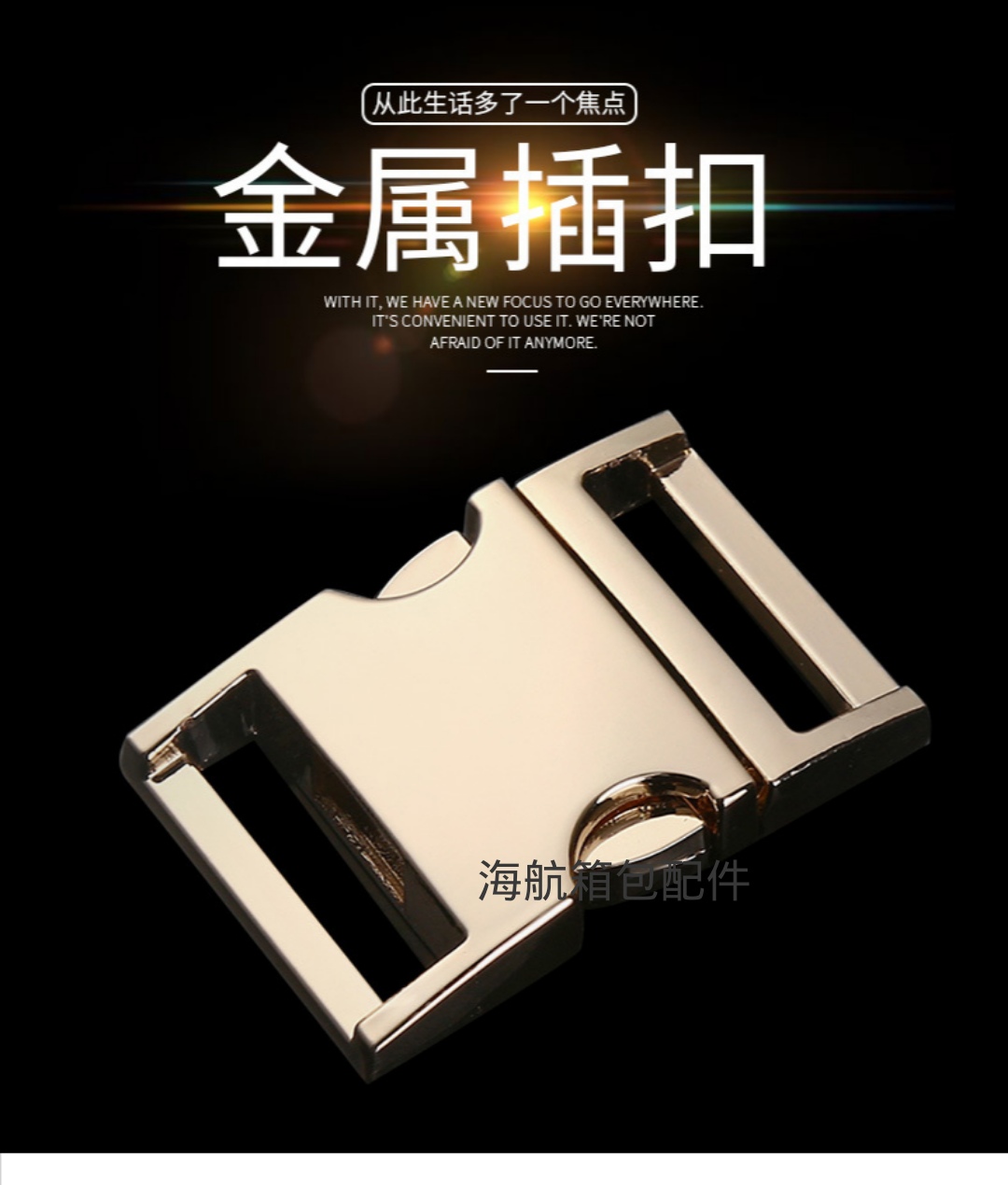

high quality Metal Fasteners: Ideal for strong and durable woven belts

When we talk about the quality and appearance of woven belts, few people will notice the "heroes" hidden behind them-metal fasteners. However, it is these small but vital parts that determine the texture and life of the entire product.

As one of the core factors of quality and appearance, metal fasteners are not only the main tool for connecting fabrics, but also directly affect the overall design beauty. Whether it is used for decorative embellishment on clothing boxes or functional realization in the field of hardware accessories, a high-quality metal fastener can make the finished product glow with a more professional and upscale atmosphere.

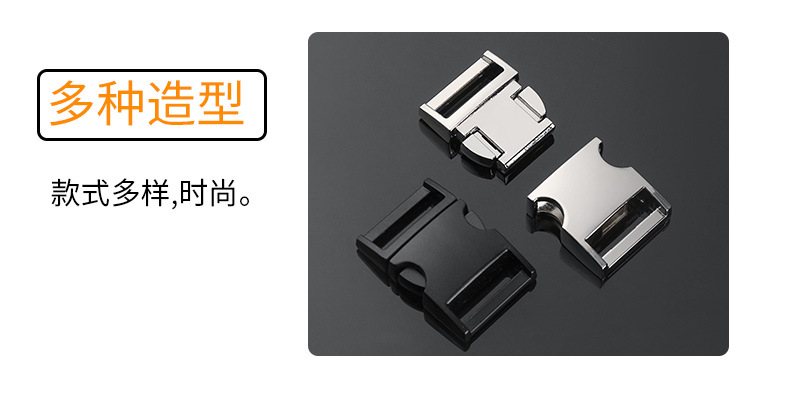

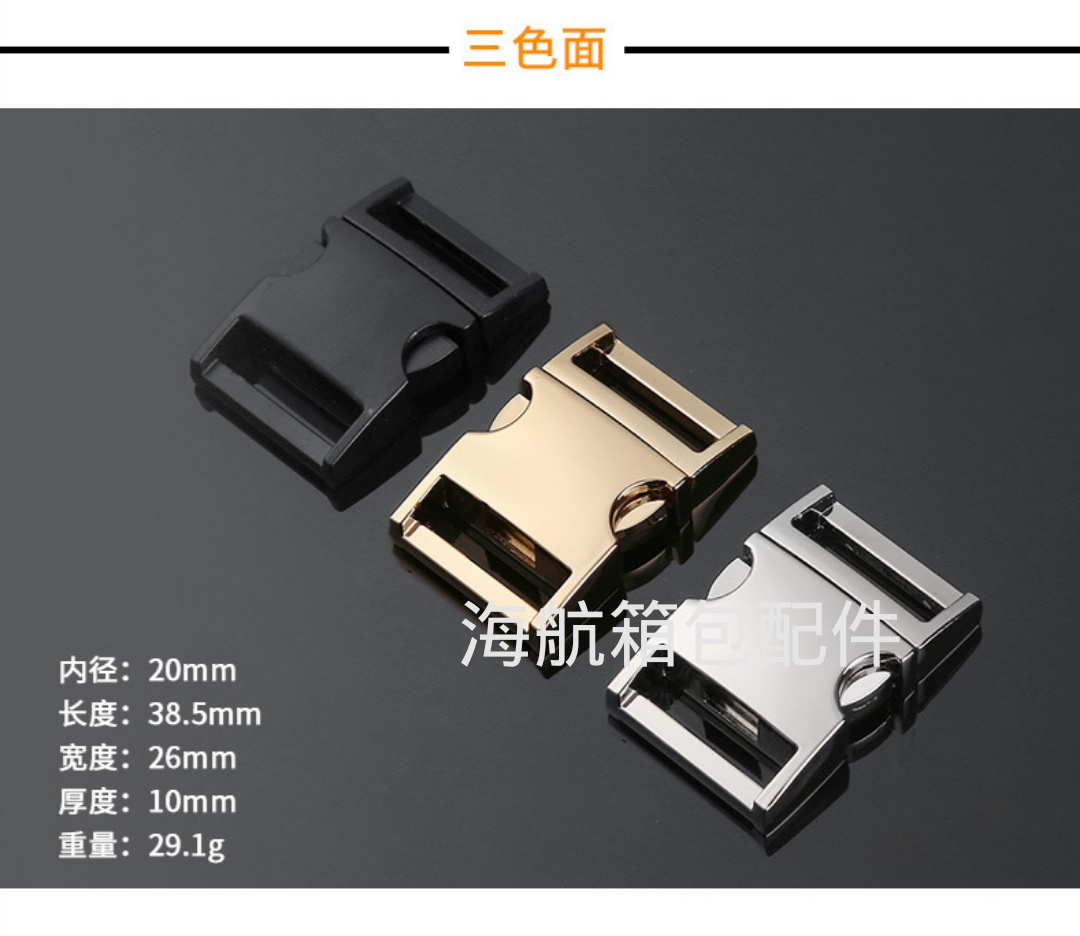

Before choosing a metal fastener, it is necessary to understand its material characteristics. At present, the mainstream market uses stainless steel, aluminum alloy and other alloy materials:

Stainless steel is highly regarded for its excellent corrosion resistance, especially for long-term use in humid environments; at the same time, it also has extremely high strength performance, which is very suitable for product types that need to withstand large tensile forces.

In contrast, aluminum alloys stand out with the advantages of light and easy processing, especially in the pursuit of weight control applications is particularly important. And after proper surface treatment, you can also get a very bright visual effect.

In addition to the two main options mentioned above, some other types of special alloys are also used in some high-end custom projects. They often combine their unique attributes in one, and they can better reflect their differences in meeting basic functional needs.

The practical application of metal fasteners is far more than limited to the traditional leather products industry. In fact, from the common backpack shoulder straps in daily life to the climbing rope fixtures required for outdoor equipment, etc., you can see its active figure and play an important role.

So for ordinary consumers, how can they pick out a metal fastener that really suits their needs? Here are a few simple but practical suggestions for reference:

first of all, factors such as the specific purpose direction and the expected load should be clearly defined and taken into account; The second is to pay attention to the degree of fine workmanship, such as whether the edge is smooth, round and burr-free, and other details cannot be ignored. In addition, don't forget to check the relevant certification identification information! Only products purchased through formal channels and supported by authoritative testing reports are trustworthy.

The last point is about supplier selection. A good manufacturer can not only provide high quality and stable supply guarantee plus perfect after-sales service system to support the process of customer confidence building is very important. Therefore, we strongly recommend that we should give priority to those large-scale enterprises with a long history and good reputation.

In short, in this era where attention to details determines success or failure, behind every seemingly insignificant small part actually contains infinite wisdom crystals waiting to be discovered. I hope today's sharing can provide more ideas and inspiration for everyone to buy suitable metal fasteners in the future ~