History and Development of Metal Fasteners

Metal fasteners have a long history as a traditional hardware accessory. As early as ancient times, metal fasteners were widely used in military equipment and daily life because of their strong and durable characteristics. Over time, metal fasteners have evolved from simple functional components to today's diversified and high value-added products. The development of modern industrial technology, especially the breakthrough of precision casting and surface treatment technology, has significantly improved the strength, corrosion resistance and aesthetics of metal fasteners. Nowadays, metal fasteners have been widely used in many fields such as clothing boxes, hardware fasteners and woven belt buckles.

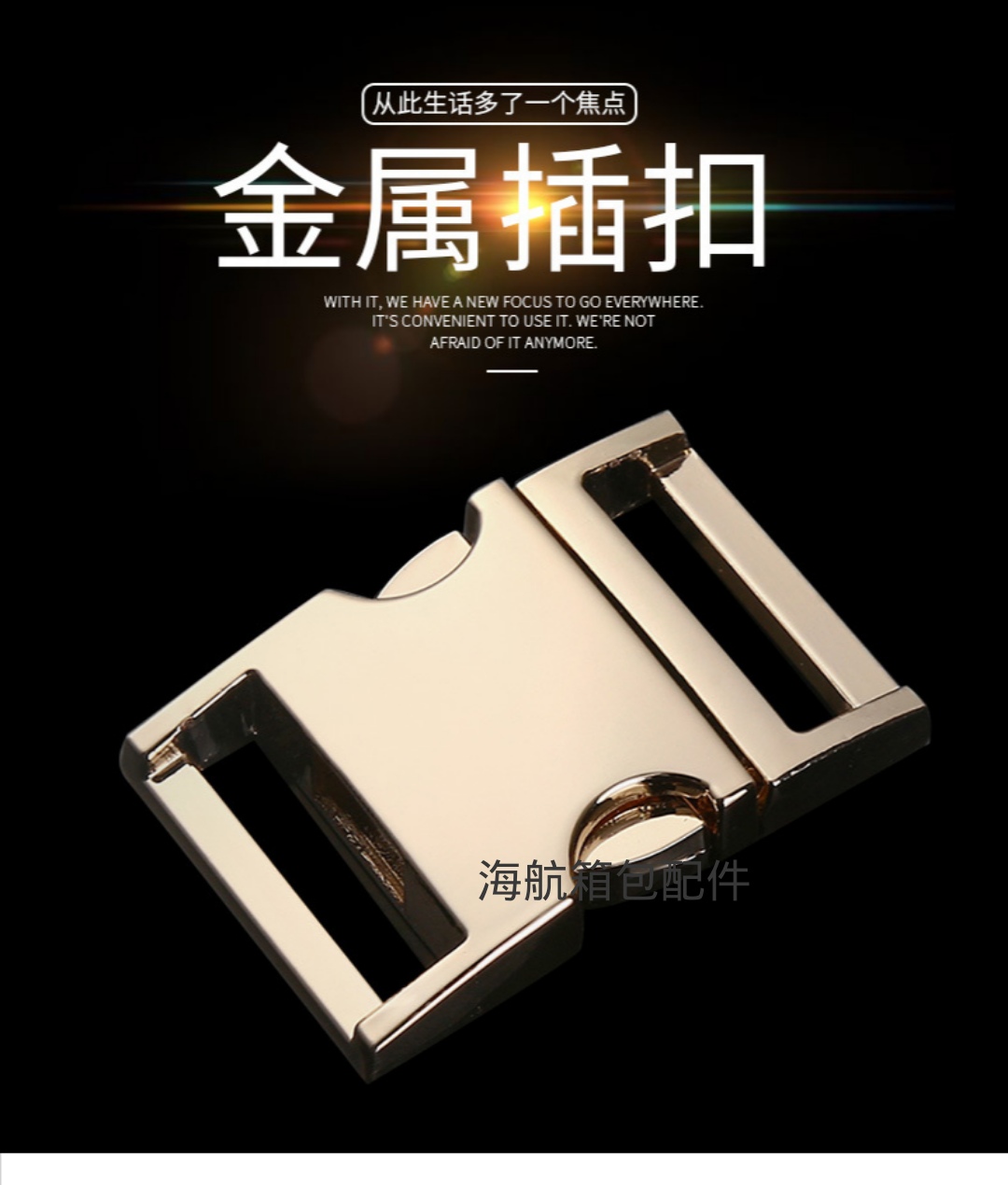

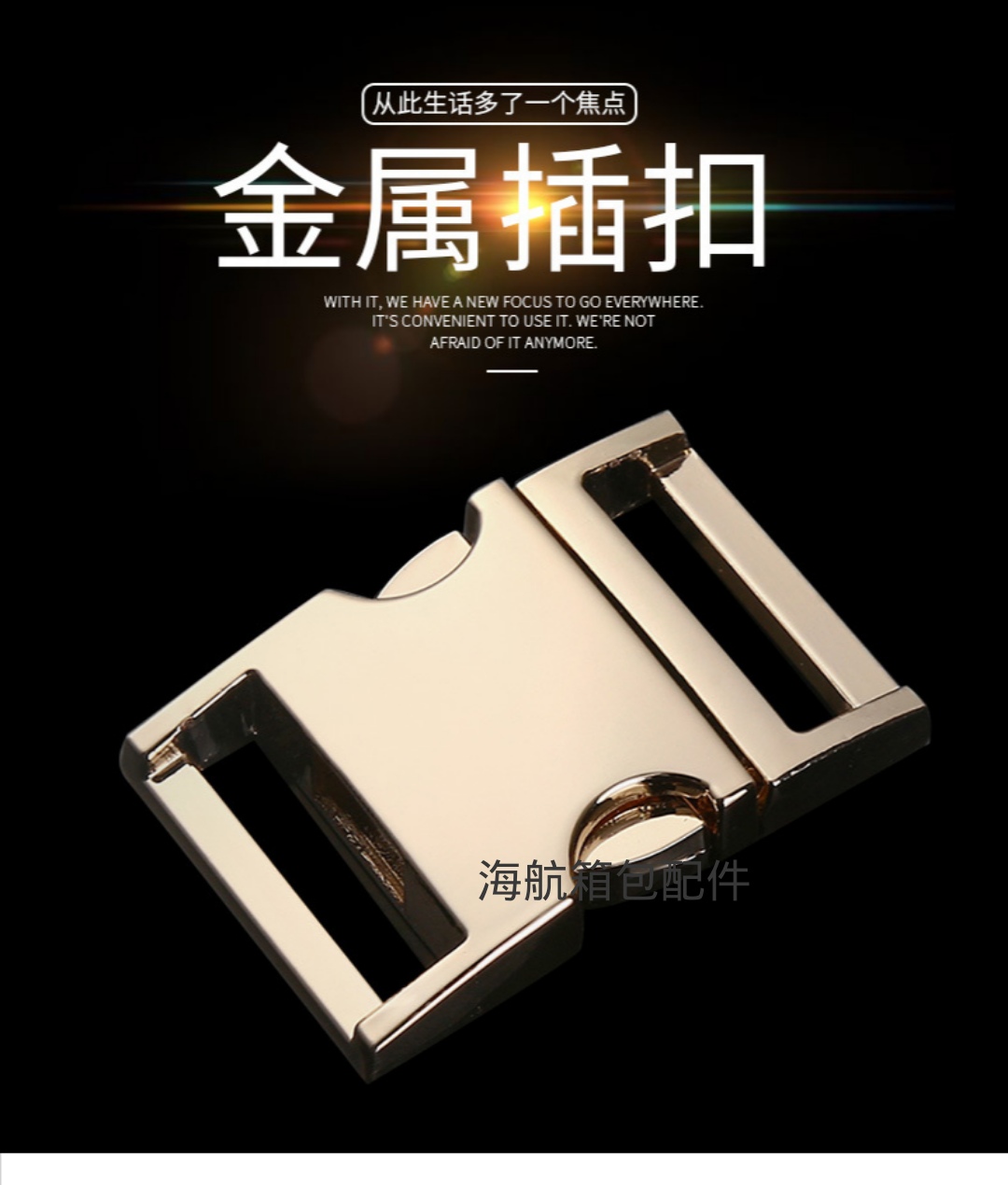

Advantages of high quality Metal Fasteners

high quality metal fasteners are popular for their excellent performance and appearance. In the material selection, high quality metal fasteners usually use stainless steel, zinc alloy and other high-quality materials, with excellent corrosion resistance and wear resistance. In the surface treatment process, through electroplating, sandblasting, wire drawing and other treatment methods, not only improve the durability of the product, but also give it a unique texture and luster. Through specific cases, we can see the outstanding performance of high quality metal fasteners in practical applications. Whether it is the fine decoration of high-end clothing boxes or the high-strength fixing of outdoor sports belts, high quality metal fasteners can be perfectly competent.

Application fields of metal fasteners

Metal fasteners are widely used in garment boxes, hardware fasteners and woven belt buckles. In the clothing box, the metal fastener is not only a closing device, but also a decorative element. The common design styles are classical, simple and luxurious. Among the hardware fasteners, metal fasteners are mainly used for connection and fixation, with high functional requirements and strong load-bearing capacity and stability. In woven belt buckles, metal fasteners must not only be beautiful, but also strong and durable to meet various needs for daily use. Through the analysis of examples, it can help readers better understand and choose suitable metal fasteners.

Production Technology and Quality Control

Professional production technology and strict quality control are important links to ensure the high quality of metal fasteners. The production process of metal fasteners includes key steps such as mold design, stamping and surface treatment. The mold design determines the shape and dimensional accuracy of the product, the stamping forming ensures the structural strength of the product, and the surface treatment improves the appearance quality and corrosion resistance of the product. In terms of quality inspection, the company will conduct inspections in strict accordance with international standards to ensure that every piece of metal fasteners that leave the factory meets high standards.

Optional Guide: How to Choose high quality Metal Fasteners

In the face of a dazzling array of metal fasteners on the market, how to pick out the most suitable products for you? First of all, pay attention to material identification, choose stainless steel, zinc alloy and other high-quality materials made of metal fasteners. Secondly, observe the surface treatment, electroplating, sandblasting, wire drawing and other processes can make the metal fastener more texture and luster. Finally, the choice of well-known brands, well-known brands of metal fasteners are usually more secure quality. Through these practical suggestions, you can help readers easily choose a satisfactory metal fastener.

User feedback: real experience

Real user feedback is the best proof of product quality. We have collected some users' evaluation and experience, so that they can share their feelings and experiences of using metal fasteners. A business owner engaged in garment box manufacturing said: "Since the use of high quality metal fasteners, our products have received a good response in the market, and customers are very satisfied with the quality and appearance of the products." Another outdoor sports enthusiast said: "This woven belt buckle is not only beautiful, but also very strong. It will not loosen even in harsh environments. It is my best companion for outdoor activities." This truthful feedback not only increases the credibility of the product, but also provides more reference information for potential buyers.

Future trends: prospects for metal fasteners

With the progress of science and technology and the change of market demand, what are the future development trends of metal fasteners? Combined with the current market dynamics and technology frontier, we can foresee the following development directions. First of all, the application of new materials will further enhance the performance of metal fasteners, such as lightweight high-strength alloys and nanomaterials. Secondly, intelligent manufacturing technology will improve production efficiency and quality control level, and realize the balance between personalized customization and mass production. Finally, the concept of green environmental protection will encourage enterprises to take more environmental protection measures in the production and packaging process to reduce resource waste and environmental pollution. Through forward-looking analysis, we can help readers grasp the future development of the industry.

recommend Products: Selected high quality Metal Fasteners

In order to make it easier for readers to find high-quality metal fasteners, we have selected several products with good reputation in the market and introduced their characteristics in detail. The first is a stainless steel fastener suitable for clothing boxes, the surface is polished, smooth and bright, easy to install. The second is a zinc alloy fastener for hardware fasteners, compact structure, strong load-bearing capacity, suitable for the connection and fixation of heavy equipment. The third is a woven belt buckle, made of copper alloy material, surface gold-plated treatment, both beautiful and durable. Whether you are used for clothing boxes, hardware fasteners or woven belt buckles, there is always one that can meet your needs.