Design inspiration: evolution from traditional to modern

As a connecting device with a long history, metal fasteners have undergone a transformation from original hand-forged to modern mass production. Early metal fasteners mainly rely on the experience and skills of craftsmen to produce, each piece of work is full of artistic flavor. With the passage of time, with the progress of science and technology, the current metal fasteners can be accurately processed by advanced mechanical equipment, which greatly improves the production efficiency and the consistency of the finished product.

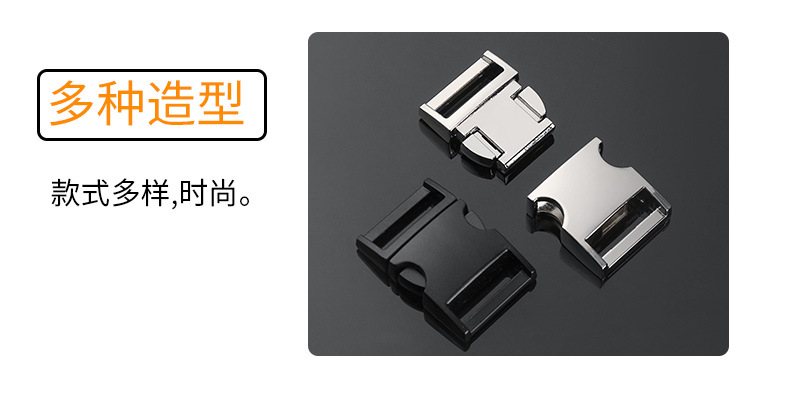

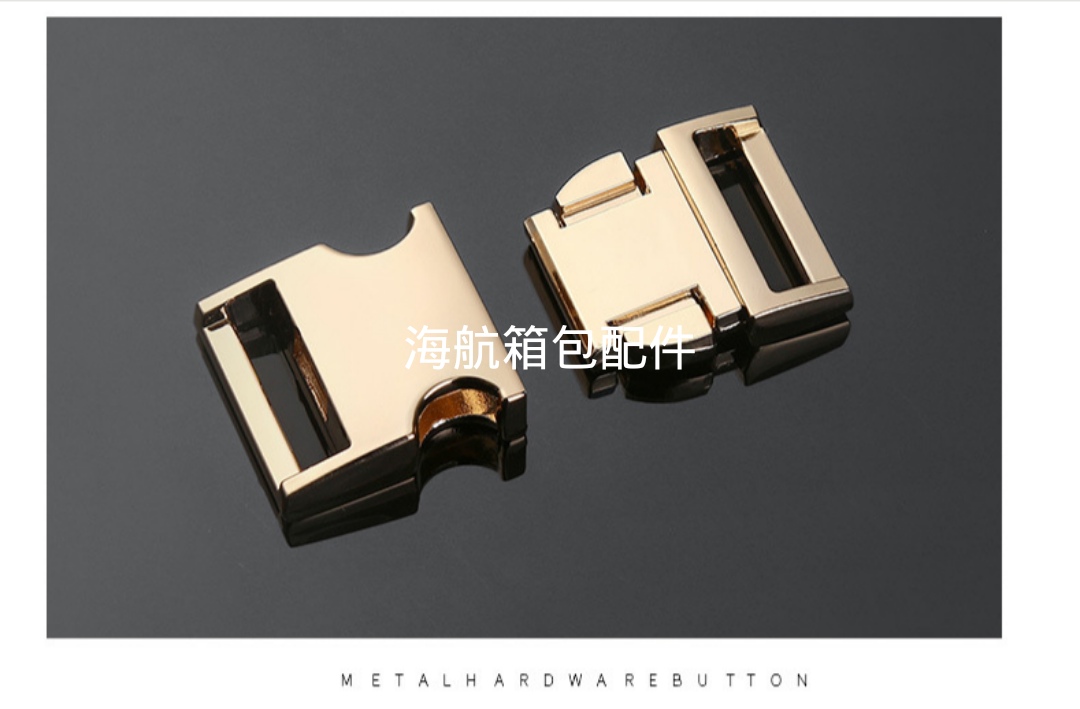

In terms of design concept, modern metal fasteners pay more attention to the combination of practicality and aesthetics. Designers combine classical aesthetics with contemporary trends, and have developed a series of new metal fasteners with traditional charm and characteristics of the times. Whether it appears as a decorative element in high-end clothing boxes or plays an important role in various hardware products, these exquisite metal fasteners can always stand out among many products and show extraordinary charm.

Materials Science: The Core Secrets of Ruggedness

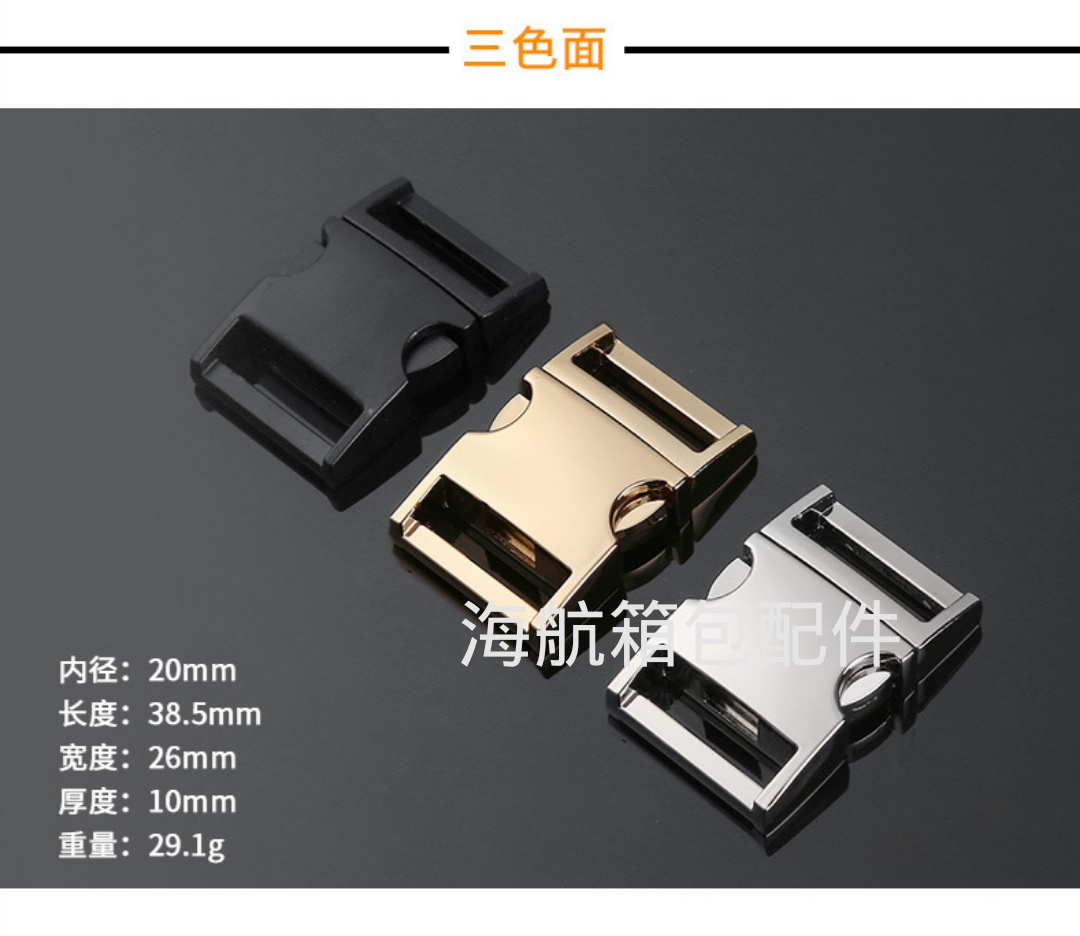

High-quality materials are one of the key factors to ensure the stable performance of metal fasteners. This series of products are made of a variety of high-grade alloy materials such as stainless steel and brass. Stainless steel is known for its excellent corrosion resistance and will not rust easily even if exposed to humid environments for a long time. Brass is favored because of its bright color and good ductility, and is often used to make fasteners that need to be disassembled frequently.

In addition, all metal parts undergo special surface treatment processes, such as electroplating, sandblasting, etc., to further enhance their wear resistance and corrosion resistance, so that these metal fasteners can maintain even in the face of harsh working conditions Long service life. It is such an attitude of excellence that has created a unique high-quality metal fastener on the market.

Fine craftsmanship: every detail is ingenious

Behind every success there are countless figures of hard work. In the production workshop, workers are busy polishing each piece of metal fasteners. From the initial selection of raw materials to the final inspection of the finished product, every link can not be ignored. Especially in the key processes, such as laser cutting, CNC machine tool processing, ultrasonic welding, etc., it strictly follows international standards and strives to do the best.

Through the continuous optimization and improvement of the production process, we have not only improved the qualified rate of products, but also greatly reduced the scrap rate. Behind every technological innovation is another breakthrough in our own strength. Now, when you hold such a metal fastener in your hand, you might as well take a closer look. You will find that not only the traces of time are left on it, but also the sweat and wisdom of the craftsmen.

Application Scenario: Multi-purpose Solution Provider

With excellent performance and wide compatibility, our metal fasteners can be found in almost any field. In the home textile industry, it is the best companion for custom wardrobes and drawer handles; in the automobile manufacturing industry, it can firmly fix interior panels; even in outdoor adventure equipment, it has its strong support. Whether it's a lightweight textile or a hard sheet metal, these metal fasteners can handle the challenge with ease.

Taking a high-end travel backpack as an example, the designer chose our stainless steel buckle as the shoulder strap adjuster. Since this backpack is mainly used for long-distance hiking, the requirements for materials are extremely demanding. Facts have proved that this stainless steel buckle not only meets all the expectations of the designer, but also wins the love of consumers in the actual use process. This is just the tip of the iceberg, there are more possibilities waiting to be excavated in the future.

Installation Guide: Easy and Seamless Integration

In order to make every customer enjoy the most convenient service experience, we have specially compiled a detailed installation manual. In this manual, you will learn about the preparation work before and after the installation of the metal fastener, the list of required tools, the operation method of each step and so on. Even novices with no relevant experience can easily get started.

For different substrate types, we provide corresponding installation suggestions. For example, on a wooden surface, it is recommended to drill holes before screwing; on a metal panel, you can directly use self-tapping screws for fastening. In addition, if you encounter more complex assembly tasks, you can also contact our customer service team for professional technical support.

Nursing Knowledge: Tips to Extend Life